Mining Hardware Lifecycles: Upgrading for Optimal Performance

In the heart of every mine, amidst the hum of machinery and the precision of operations, lies the beating pulse of mining hardware. Its journey spans from deployment to obsolescence, with each phase impacting the performance, economics, and ecological footprint of mining operations. Unraveling the intricacies of this lifecycle is essential for mining enterprises aiming to unlock the full potential of their operations. Moreover, it highlights the pivotal role of upgrading as a catalyst for maintaining operational excellence, addressing challenges, and embracing technological shifts. By embarking on this exploration, stakeholders within the mining industry can arm themselves with knowledge to make informed decisions that harmonize productivity with sustainability.

The Importance of Upgrading Mining Hardware

In the fast-paced world of mining, staying ahead demands more than just brute force and heavy machinery. The strategic upgrading of mining hardware emerges as a crucial factor in ensuring operations remain competitive, efficient, and compliant with evolving standards. This section delves into the significance of upgrading mining hardware, highlighting its benefits and challenges.

Benefits of Upgrading:

- Improved Performance and Efficiency: Upgrading mining hardware infuses operations with a fresh wave of power and efficiency. Newer technologies often bring increased processing capabilities and optimized energy consumption, resulting in faster and more effective resource extraction. This leads to higher productivity levels, better utilization of resources, and ultimately, enhanced profitability.

- Enhanced Safety and Reduced Downtime: Modern mining hardware incorporates advanced safety features and real-time monitoring systems that minimize the risk to both equipment and personnel. Additionally, upgraded hardware is less prone to breakdowns, leading to reduced downtime and increased operational uptime. This translates to consistent production levels and lower maintenance costs.

- Compliance with Changing Regulations: The mining industry operates within a framework of ever-evolving regulations aimed at promoting environmental responsibility and worker safety. Upgrading hardware allows mining companies to adapt to these changes seamlessly, ensuring compliance and averting potential legal and financial pitfalls.

Strategies for Upgrading Mining Hardware

In the dynamic world of mining, the strategic upgrade of hardware can mean the difference between mediocrity and excellence. Navigating this process requires careful planning and a clear roadmap. This section uncovers essential strategies that mining companies can employ to ensure seamless hardware upgrades while maximizing benefits.

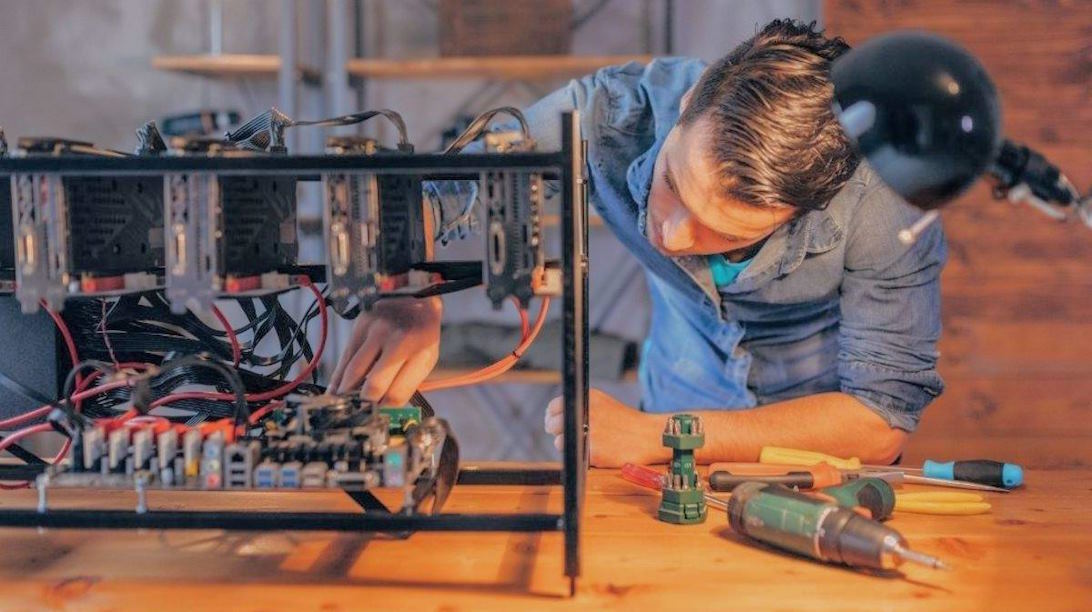

Regular Performance Monitoring and Assessment:

Consistent monitoring of hardware performance forms the bedrock of successful upgrades. By gathering data on metrics like efficiency, output, and maintenance requirements, mining enterprises can pinpoint when their equipment is approaching obsolescence. Regular assessments offer insights into performance trends, helping decision-makers identify the right time to initiate upgrades.

Identifying Optimal Upgrade Points:

Understanding the lifecycle stages of mining hardware is crucial in identifying optimal upgrade points. These junctures, where hardware performance begins to plateau, offer opportunities to infuse new technologies and capabilities into operations. Careful consideration of these points ensures that upgrades align with operational requirements and long-term goals.

Cost-Benefit Analysis of Upgrades:

Conducting a thorough cost-benefit analysis is paramount before embarking on any upgrade endeavor. Mining companies must weigh the upfront costs of hardware replacement or enhancement against projected gains in efficiency, productivity, and cost savings. This analysis helps in making informed decisions and justifying investments to stakeholders.

Technological Trends Impacting Upgrades

The mining industry stands at the precipice of a technological revolution, where hardware upgrades have taken on a new dimension, driven by transformative innovations. This section delves into the pivotal technological trends that are shaping the upgrade landscape, ensuring mining operations remain agile, efficient, and future-ready.

Evolution of Mining Hardware Technologies:

- Processing Power and Energy Efficiency: The evolution of mining hardware is characterized by a relentless pursuit of increased processing power coupled with enhanced energy efficiency. Newer hardware models boast higher hash rates while consuming less energy per computation, resulting in improved performance and reduced operational costs.

- Integration of AI and Automation: The integration of Artificial Intelligence (AI) and automation has revolutionized mining operations. AI algorithms optimize mining processes by analyzing vast amounts of data in real time, leading to predictive maintenance, improved decision-making, and enhanced resource utilization.

- Internet of Things (IoT) Integration: The Internet of Things (IoT) has found its way into mining hardware, connecting various components and equipment to a centralized network. This enables remote monitoring, real-time diagnostics, and the ability to proactively address potential issues, leading to reduced downtime and increased operational efficiency.